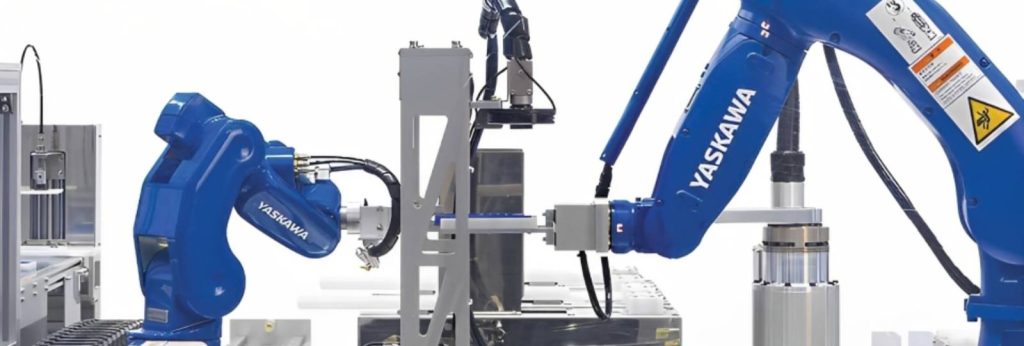

The world of industrial robotics is always advancing, with modern innovations and patterns forming the scene of fabricating and computerization. As we step into 2023, it becomes vital for businesses to remain educated about the most recent improvements in industrial robotics and how to use these patterns to pick up a competitive advantage. In this web journal, we’ll investigate the beat seven industrial robotics patterns of 2023 and talk about techniques to saddle their potential.

Industrial robots have been at the cutting edge of revolutionizing fabricating forms for a long time, and their significance proceeds to develop in 2023. The most recent patterns are centered on moving forward proficiency, security, and versatility, empowering businesses to optimize their operations and remain competitive in a quickly changing market.

Trend 1: Collaborative Robots (Cobots) Reclassifying Workspaces

Collaborative robots, or cobots, are planned to work nearby human laborers, upgrading efficiency and security. Not at all like conventional robots, cobots are simple to program and require a negligible security framework, making them perfect for small and medium-sized undertakings. In 2023, we are able anticipate seeing more industries receiving cobots to handle dreary errands, permitting human specialists to center on more complex and imaginative perspectives of production.

Trend 2: Integration of Artificial Insights and Machine Learning

Artificial Insights (AI) and Machine Learning (ML) are changing industrial robotics by empowering robots to memorize from data, adjust to changes, and make choices independently. AI-powered robots can optimize their possessive forms, anticipate support prerequisites, and distinguish inconsistencies in real-time. Coordination AI and ML in industrial robotics will lead to more cleverly, productive, and self-optimizing generation lines.

Trend3: Headways in Vision-Guided Robotics

Vision-guided robotics is progressing quickly, empowering robots to see and translate their environment precisely. High-resolution cameras and modern calculations enable robots to perform complex errands with exactness. This slant will discover applications in quality control, gathering, and pick-and-place assignments, upgrading generally fabricating efficiency.

Trend 4: Mobile Robotics for Adaptability and Scalability

Mobile robotics, counting Independent Versatile Robots (AMRs) and Mechanized Guided Vehicles (AGVs), are picking up ubiquity due to their adaptability and versatility. These robots can explore energetic situations without the need for a settled foundation. In 2023, we’ll witness expanded selection of versatile robots to optimize fabric dealing with, stockroom coordinations, and intralogistics processes.

Trend 5: Security Improvements in Robotic Systems

Ensuring the safety of human specialists and robots working together is of most extreme importance. In 2023, able to anticipate critical headways in security highlights, such as made strides sensor technologies, collaborative control calculations, and real-time checking. These upgrades will make more secure workspaces and quicken the selection of mechanical autonomy in businesses with exacting security regulations.

Trend 6: Robotics as a Benefit (RaaS) Model

The Robotics as a Benefit (RaaS) demonstrate is picking up footing as an elective to capital-intensive robot speculations. RaaS permits businesses to get to robotics arrangements on a membership premise, lessening forthright costs and support obligations. In 2023, the RaaS demonstration will make industrial robots more open to little businesses and encourage their passage into automation.

Trend 7: Computerized Twin Innovation in Robotics

Digital twin technology makes virtual copies of physical robots, permitting for real-time observing, reenactment, and prescient upkeep. Producers can analyze data from computerized twins to optimize robot execution, avoid downtime, and make strides in general operational productivity. In 2023, computerized twin technology will revolutionize robot support and execution management.

How to Use Industrial Robotics Patterns in 2023

To tackle the total potential of industrial robotics patterns in 2023, businesses ought to consider the taking after strategies:

Conduct a Robotics Preparation Appraisal:

Assess your current fabricating forms and recognize assignments that can be automated utilizing the most recent mechanical autonomy patterns. Get it the ROI and long-term benefits of receiving these technologies.

Invest in Representative Preparing:

As mechanical technology has become more predominant in work environments, it is fundamental to upskill your workforce to work nearby robots viably. Representatives preparing on robot programming and collaboration will guarantee a smooth move to computerized workflows.

Collaborate with Robotics Suppliers:

Collaborating with reputable robotics suppliers can assist you get to cutting-edge advances without overwhelming capital ventures. Consider the RaaS demonstration as a cost-effective approach to presenting robotics into your operations.

Implement Security Measures:

Prioritize the security of your representatives and robots by actualizing security conventions, such as chance evaluations, security preparing, and collaborative workspace design.

Adopt a Versatile Approach:

Begin little with pilot ventures to test the possibility of automated executions. Once fruitful, continuously scale up to maximize the benefits of mechanical robotics.

Conclusion

The year 2023 presents an energizing scene for industrial robotics, with modern patterns promising to revolutionize fabricating and computerization. Collaborative robots, AI integration, vision-guided frameworks, and versatile robotics are some zones where noteworthy progressions are anticipated. By remaining educated around these patterns and deliberately leveraging them, businesses can improve efficiency, progress security, and remain competitive in a progressively computerized world.