Engineering automation has been revolutionizing the manufacturing industry for many years. By utilizing various automated technologies, engineering automation has improved manufacturing processes, increased efficiency, and reduced production costs. In this blog, we will explore the concept of engineering automation and how it is revolutionizing the industry.

Engineering automation involves the use of advanced technologies, such as robotics, artificial intelligence, and machine learning, to automate manufacturing processes. By doing so, engineering automation reduces the need for manual labor and improves the quality and consistency of production. Some of the key technologies used in engineering automation include:

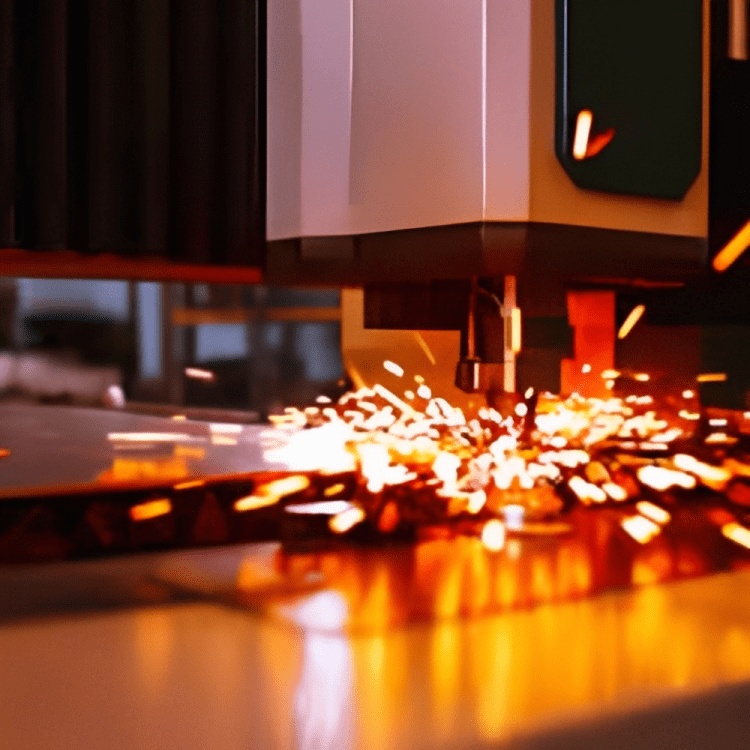

- Robotics: Robots are used in manufacturing to perform repetitive tasks with high precision and speed. They can also perform tasks that are hazardous to human workers, such as working in high-temperature environments or handling hazardous materials.

- Artificial intelligence (AI): AI is used to control and optimize manufacturing processes by analyzing data and making decisions based on that data. This allows manufacturers to optimize their processes, reduce waste, and improve efficiency.

- Machine learning: Machine learning is a subset of AI that involves training machines to learn from data and improve their performance over time. This technology can be used to optimize manufacturing processes and improve product quality.

Engineering automation has numerous benefits for manufacturers. One of the main advantages is increased efficiency. By automating repetitive tasks and optimizing processes, engineering automation reduces production times and improves overall efficiency. This, in turn, increases productivity and reduces costs, allowing manufacturers to produce more products at a lower cost.

Another advantage of engineering automation is improved quality control. Automated machines can perform tasks with a high degree of precision and accuracy, reducing the likelihood of errors and defects in the final product. This improves product quality and reduces the need for manual inspection and rework.

Engineering automation also has the potential to create new job opportunities in the manufacturing industry. While some manual labor jobs may be replaced by automation, there is an increasing need for skilled workers who can design, program, and maintain automated machines. This creates new job opportunities for engineers, technicians, and other skilled workers.

The future of engineering automation is bright. As technology continues to advance, we can expect to see even more innovative uses of automation in the manufacturing industry. For example, the Internet of Things (IoT) is becoming increasingly popular in manufacturing, allowing machines to communicate with each other and make decisions based on real-time data. This has the potential to further improve efficiency and reduce costs.

In conclusion, engineering automation is revolutionizing the manufacturing industry by reducing production times, improving quality control, and creating new job opportunities. As technology continues to advance, we can expect to see even more innovative uses of automation in the industry. By embracing these technologies, manufacturers can improve their processes and remain competitive in a rapidly changing market.

- Improved efficiency: Engineering automation reduces the need for manual labor and optimizes manufacturing processes, resulting in increased efficiency. Automated machines can perform repetitive tasks quickly and accurately, reducing production times.

- Reduced costs: Increased efficiency results in reduced production costs, allowing manufacturers to produce more products at a lower cost. Additionally, automation reduces the need for manual labor, which can be a significant expense.

- Improved quality control: Automated machines can perform tasks with high precision and accuracy, reducing the likelihood of errors and defects in the final product. This improves product quality and reduces the need for manual inspection and rework.

- Safety: Automated machines can perform tasks that are hazardous to human workers, such as working in high-temperature environments or handling hazardous materials.

- Increased productivity: Engineering automation increases productivity by reducing production times and improving efficiency.

- New job opportunities: While some manual labor jobs may be replaced by automation, there is an increasing need for skilled workers who can design, program, and maintain automated machines. This creates new job opportunities for engineers, technicians, and other skilled workers.

- Innovation: As technology continues to advance, we can expect to see even more innovative uses of automation in the manufacturing industry. For example, the Internet of Things (IoT) is becoming increasingly popular in manufacturing, allowing machines to communicate with each other and make decisions based on real-time data.

Overall, engineering automation is revolutionizing the manufacturing industry by improving efficiency, reducing costs, improving quality control, increasing productivity, creating new job opportunities, and driving innovation. By embracing these technologies, manufacturers can remain competitive in a rapidly changing market.